Wednesday September 8, 2021 at 11:25am

How do we define Nesting?

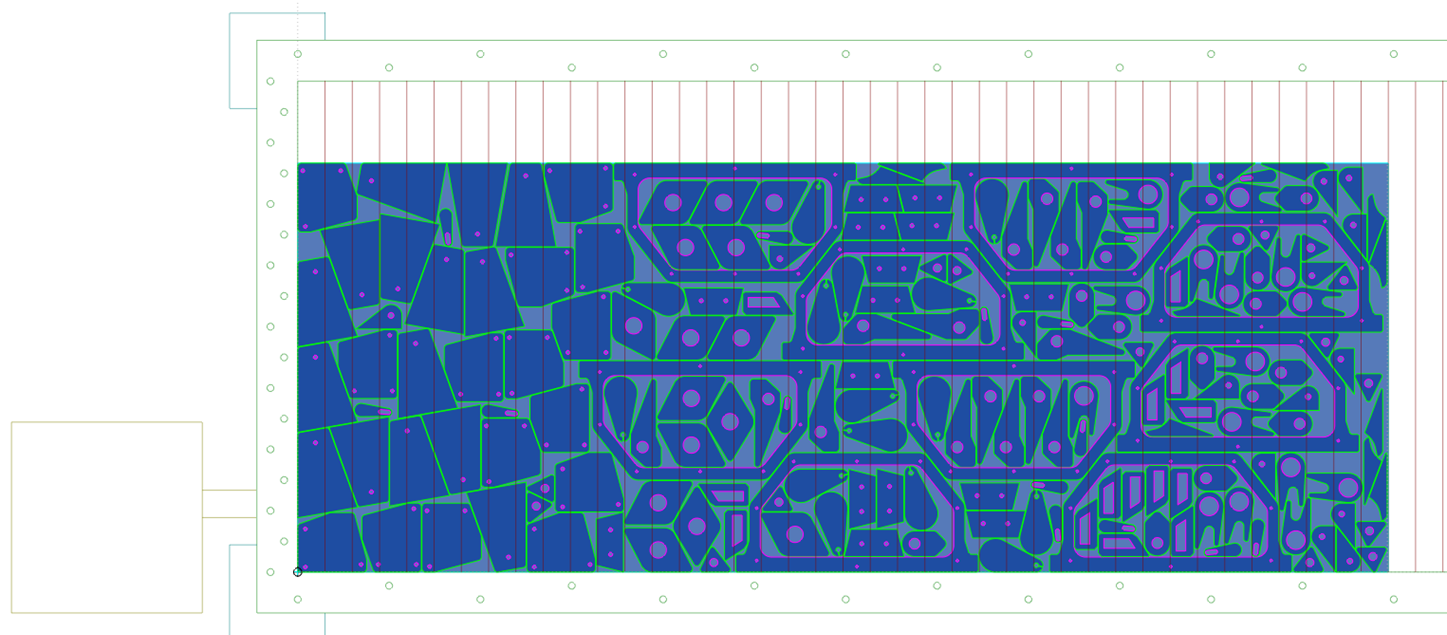

Nesting is like putting the pieces of a jigsaw together, it is the process of creating an optimal layout of your flat parts. Typically this process would be used in the sheet metal, fabric, plastic and wood/joinery markets. Nesting can also be used to align parts with a specific grain such as brushed metal products, patterned materials or wood grain.

So this then asks the question why should I nest geometry? Nesting software is designed to keep material wastage and labour costs to a minimum, along with intelligent part spacing to produce the most cost-effective toolpaths. Effective nesting can result in less time spent loading your machine with stock material, and less material scrapped whether that is MDF or Titanium.

Once we have the best fit of parts on a sheet this can be then converted to code which can run your laser, plasma, waterjet, punch, oxyfuel, knife cutter or router. With any material and any machine the key point to remember is the less scrap produced the better and nesting parts allows that to be a reality.

To begin using nesting with SOLIDWORKS there are two products that can help you start saving straight away. SigmaNEST and SWOOD Nesting.

For Sheet Metal - Sigma Nest

SigmaNEST is a great nesting package aimed at solving the challenges of nesting and cutting sheet metal. It can be used to quickly import a range of 2D and 3D filetypes, nest and then produce quote and NC data

To learn more about SigmaNEST please click here

For Wood - SWOOD Nesting

If you are manufacturing wood then SWOOD Nesting is an ideal solution. Factoring the specific needs of woodworking as well as running within SOLIDWORKS it can quickly nest your assemblies to reduce material wastage, then SWOOD CAM can be used to rapidly produce NC files specific for your CNC machine.

To learn more about SWOOD please

click here